Process Introduction

01.

Material configuration

he first step in our production process starts with ingredients, guided by the needs of customers and the market, using tungsten carbide, cobalt, and other trace elements for proportioning.

02.

Preparation of mixture

The grain size of the mixture varies from ultrafine to ultra coarse, and powders with different grain sizes need to be ball milled, screened, dried, and granulated in isolated systems to avoid mixing.

Manufacturing requirements?

03.

Press forming

We use molds to press the mixture into the desired shape and size, and in this process, we ensure quality by precisely controlling parameters such as pressure, temperature and time.

04.

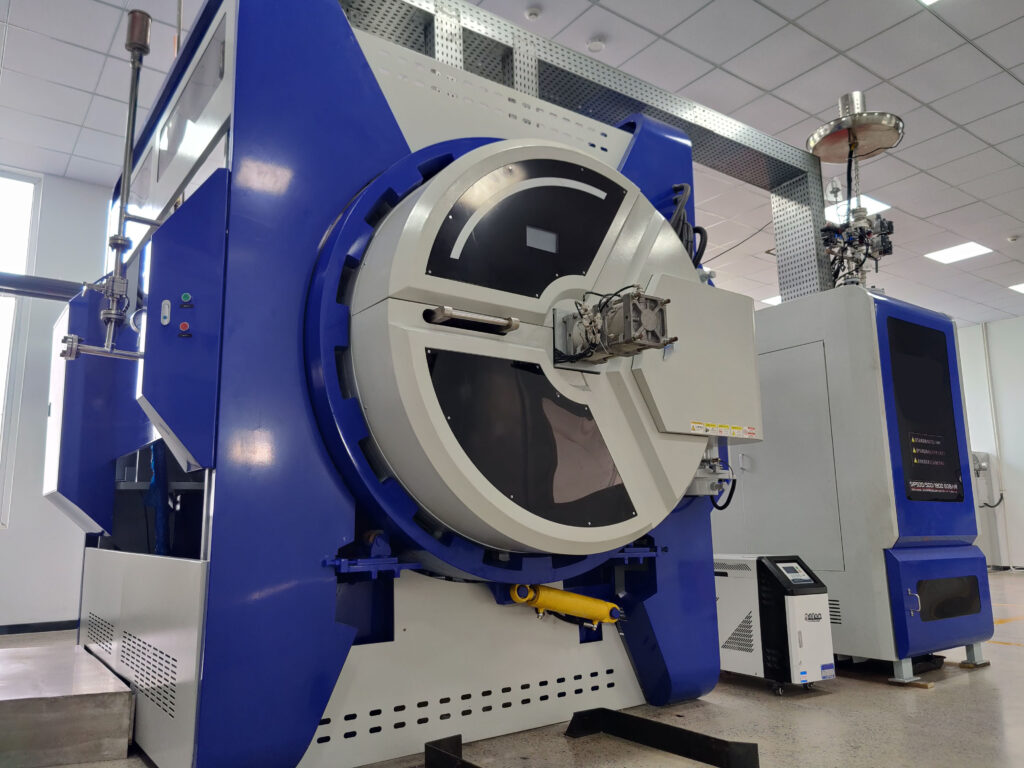

Sinter

Through vacuum and pressurized atmosphere, the hard alloy is finally sintered at a high temperature of up to about 1450 ℃, which endows it with higher physical properties to meet various demanding and complex application requirements.

05.

Grinding

According to the customer's application requirements, various surface treatment solutions are applied to the product to ensure that it meets the customer's required dimensional accuracy, shape, and surface quality.

06.

Inspection

We have our own testing center that rigorously controls the key performance indicators from raw materials, mixtures, preforms to finished products throughout the entire process, ensuring that product quality and performance meet standards before being sent to customers.

07.

Supporting facilities

To ensure smooth production, we have introduced corresponding equipment from system to equipment matching, and equipped a professional maintenance team to ensure production continuity and product quality.